[email protected]

[email protected] No. 1819, Renmin West Road, Cao'e Street, Shangyu District, Shaoxing City, Zhejiang Province, China

No. 1819, Renmin West Road, Cao'e Street, Shangyu District, Shaoxing City, Zhejiang Province, China

+86-18158752211

2024.10.07

2024.10.07 Industry News

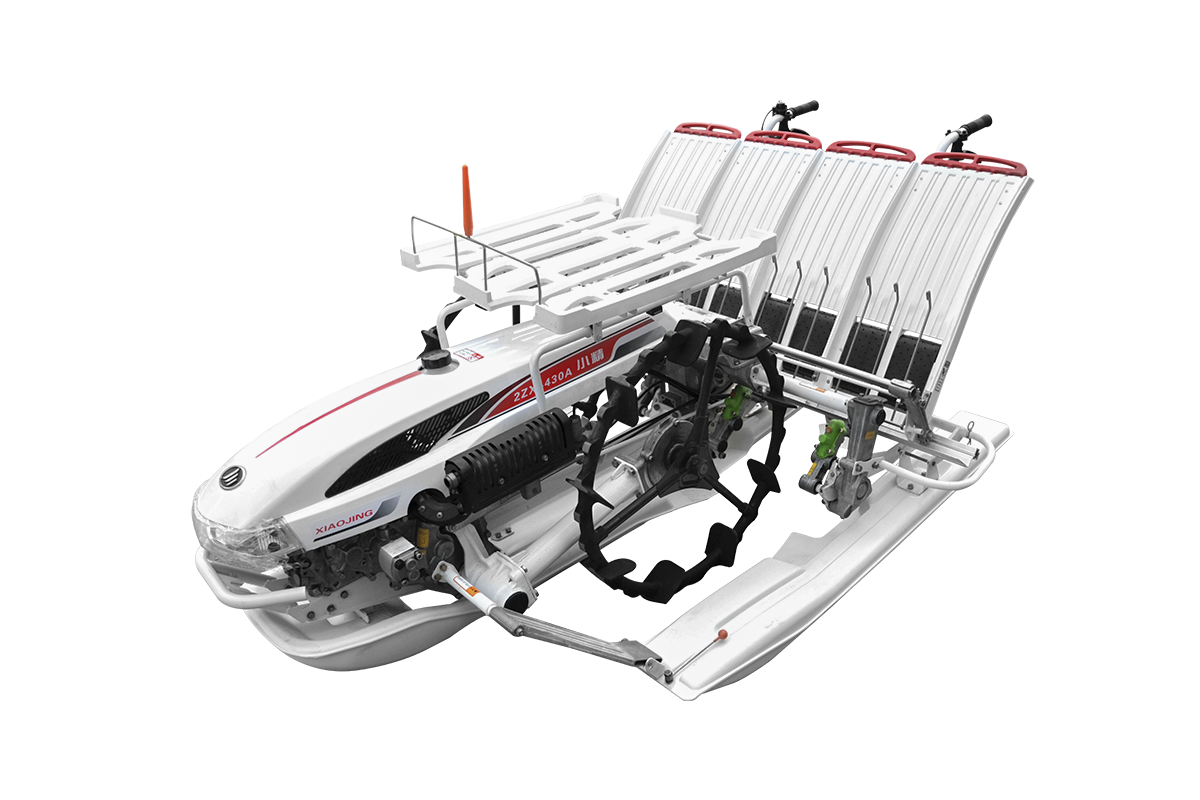

Industry NewsRice transplanter, also known as rice transplanter, is an indispensable core equipment in modern agricultural mechanized production. The design of its body structure directly affects the performance, durability and ease of operation of the whole machine, and has become an important factor in improving agricultural production efficiency.

High strength and light weight of body structure

As the core frame of the rice transplanter, the body structure must be able to withstand various loads during the transplanting process. These loads include the weight of the seedlings, the reaction force of the soil, and the weight of the machine itself. Therefore, the first consideration in the design is the high strength of the structure. Usually, the body is welded or cast with high-strength steel to ensure stability and durability in harsh farmland environments.

However, high-strength design does not mean that lightweight can be ignored. Lightweight design can not only effectively reduce the energy consumption of the machine, but also improve operational flexibility and reduce the labor intensity of farmers. Therefore, while pursuing high strength, the body structure design of the rice transplanter also focuses on achieving lightweight by optimizing the structure and selecting lightweight materials.

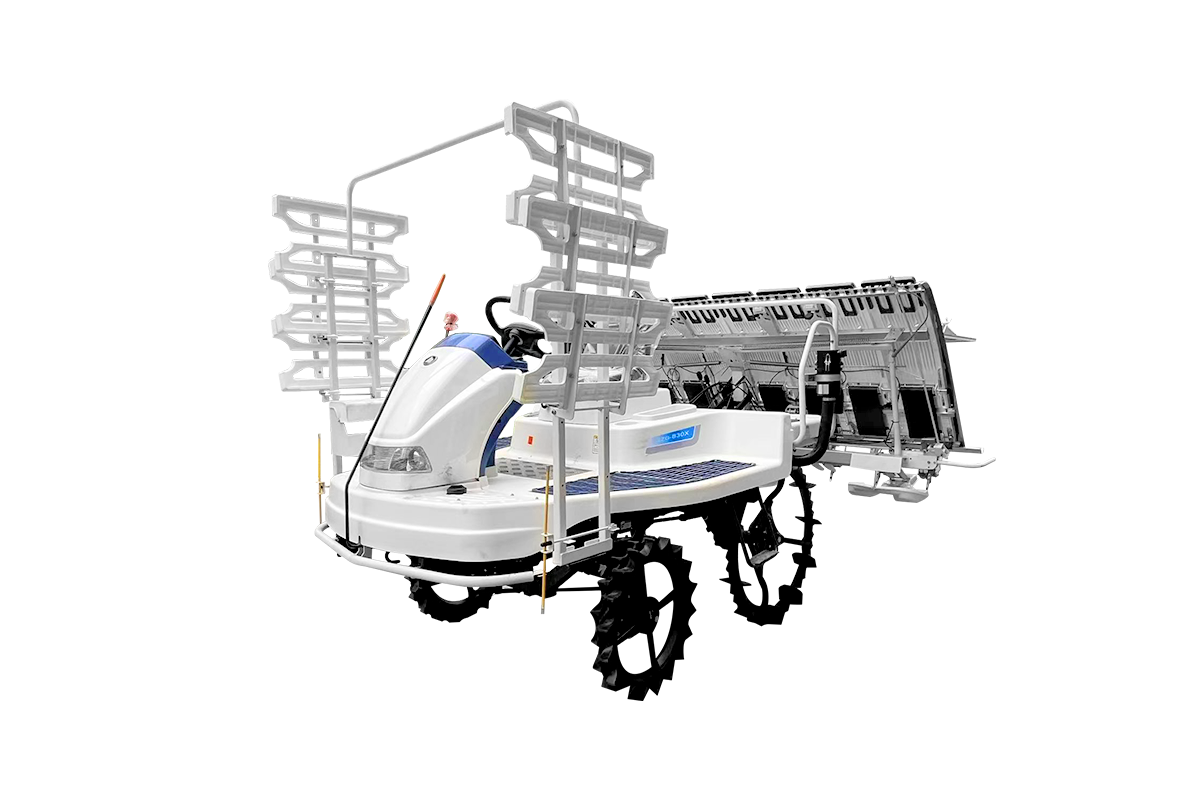

Modular and standardized design

Modularization and standardization are important trends in modern mechanical design, which also applies to the body structure design of the rice transplanter. Modular design breaks down the machine structure into multiple independent modules, each of which can be manufactured, installed and repaired independently. This design not only improves production efficiency, but also simplifies the maintenance and upgrade process of the machine.

Standardized design means that each component in the machine structure follows unified standards and specifications, which helps to reduce manufacturing costs and improve the interchangeability and versatility of components. In addition, standardized design provides farmers with more choices and flexibility, enabling them to customize suitable rice transplanters according to their needs.

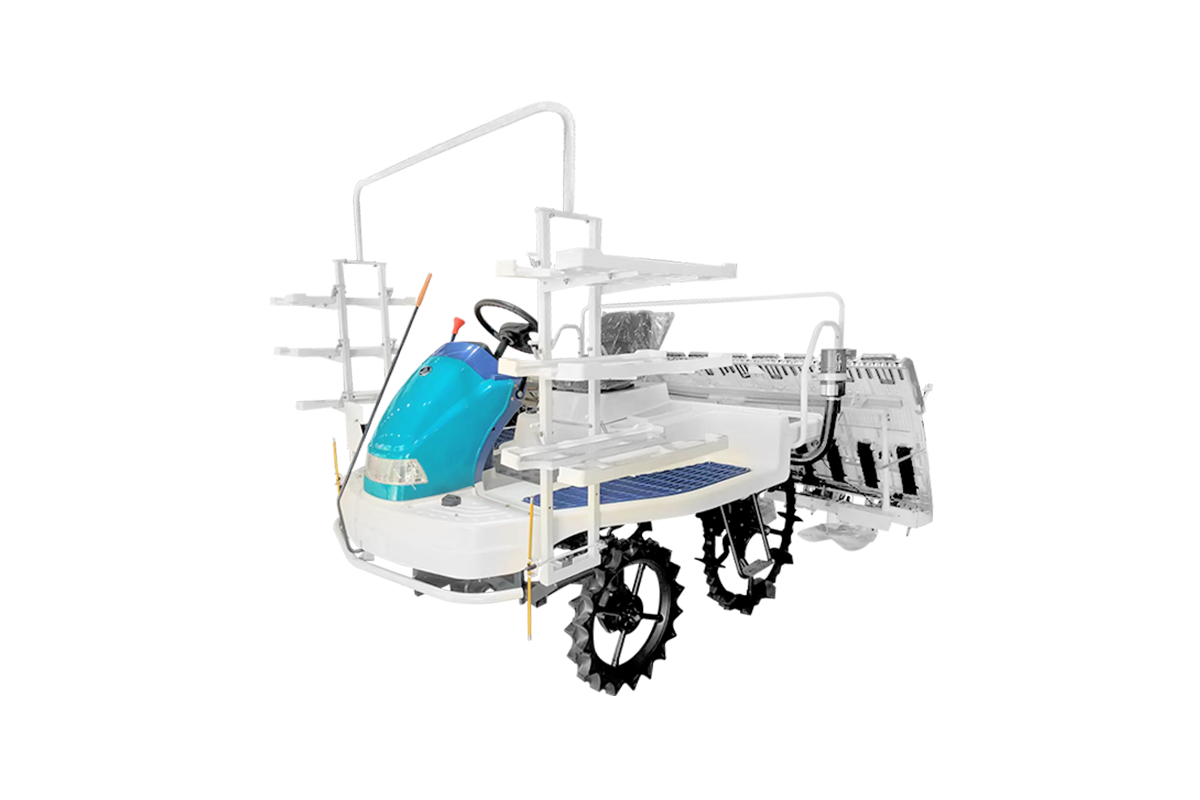

Superior passability and stability

In complex and changeable farmland terrain, rice transplanters must have good passability and stability to ensure smooth operation on various terrains. To this end, the machine structure design usually follows the principles of wide wheelbase, low center of gravity and large ground clearance. The wide wheelbase increases the support area of the machine, thereby improving stability; the low center of gravity design lowers the center of gravity of the machine and reduces the risk of rollover; the large ground clearance ensures that the machine can travel smoothly on uneven farmland, avoiding interruptions to operations due to terrain problems.

Convenient maintenance and adjustment

Rice transplanters need to be regularly maintained and adjusted during use to ensure that they are always in good working condition. Therefore, the body structure design needs to focus on convenient maintenance and adjustment functions. For example, by adopting parts that are easy to disassemble and install, and setting reasonable maintenance channels and inspection ports, farmers can easily maintain and adjust the machine. This design not only improves work efficiency, but also reduces downtime caused by equipment failure, ensuring the continuity of agricultural production.